Kirk Wright apparently built a Model T engine that produced around 200 hp. Knowing this I asked him if there was a simple way to improve the performance of my Model T pickup. He suggested that I change from standard 3.63:1 to 4:1 gears.

Stuff to do when you are 80 - Jay Leno

Ross sent in this link.

“This has been on my bucket list since I was a kid,” says car enthusiast Jay Leno of driving the Hemi Under Glass, a 2,500-horsepower Plymouth Barracuda first introduced in the 1960s, with its massive engine situated in the rear of the car, surrounded by glass, known for the way its front end rockets skyward when the driver accelerates.

Car Rallye May 27

Robb

I’m not sure if anyone is interested but this is the day before the safety inspection and anyone that does participates can leave there car in the shop overnight

They don’t have to do the rally we can just have a small car show in the parking lot.

Ted

Club Member Ken Hudgeon Passed Away

HUDGEON

Kenneth Charles

December 29, 1937 - February 20, 2017

Ken Hudgeon of Drumheller, AB, passed away after a brief illness on Monday, February 20, 2017, surrounded by family. Ken is remembered by his loving wife of 59 years, Anne; sons, Alfred (Maureen), David (Dena) and Kenny (Nancy); daughter, Tammy (Ode); grandchildren, Blair (Janine), Dylan (Krystal), Kyle (Tessa), Tyler, Adrian, Katelyn (Dustin), Courtney (Vance); great grandson, Benson; brothers, Bob (Norlene) and Don; as well as numerous nieces and nephews. Ken was born in Drumheller and grew up on the family farm at Delia. After high school, Ken left the farm and joined Canadian Utilities/Alberta Power as a lineman and serviceman. He plied his trade for twenty years, spending time in Oyen and Coronation before returning to Drumheller. In 1977, he left Alberta Power to start his own company, Hudgeon Power Systems, which he led until 2009 when he retired and handed the reins to his eldest son, Alfred. Ken was also a successful competitive stock car racer for many years. He built and raced cars around western Canada with his friends Pete Benson and Dick Smeal. At the time, he was offered an opportunity to pursue his racing career in the United States, but instead chose family and adventures in the Drumheller valley. In retirement, Ken continued to pursue his passion for cars and could typically be found working on his latest project in his Munson shop or having coffee with his friends at Joe DeMott’s shop. Ken and Anne also enjoyed quading, camping and spending time at their house on Gabriola Island, BC. A Celebration of Ken’s Life will be held on Friday, March 10, 2017 at 2:00 pm at Knox United Church, 195 - 3rd Avenue E, Drumheller, AB. In lieu of flowers, donations may be made in Ken’s memory to the Alberta Heart and Stroke Foundation of AB, #100, 119 – 14 Street NW, Calgary, AB, T2N 1Z6. Messages of condolence may be left for the family at www.myalternatives.ca. ALTERNATIVES® FUNERAL AND CREMATION SERVICES, Serving Calgary and Surrounding Areas since 1997. 403-216-5111

Barn Find

Hagerty Insurance produces a "Barn Find" video series.

They don't make them like they used to

Crash test comparison, 1959 Bel Air vs 2009 Malibu.

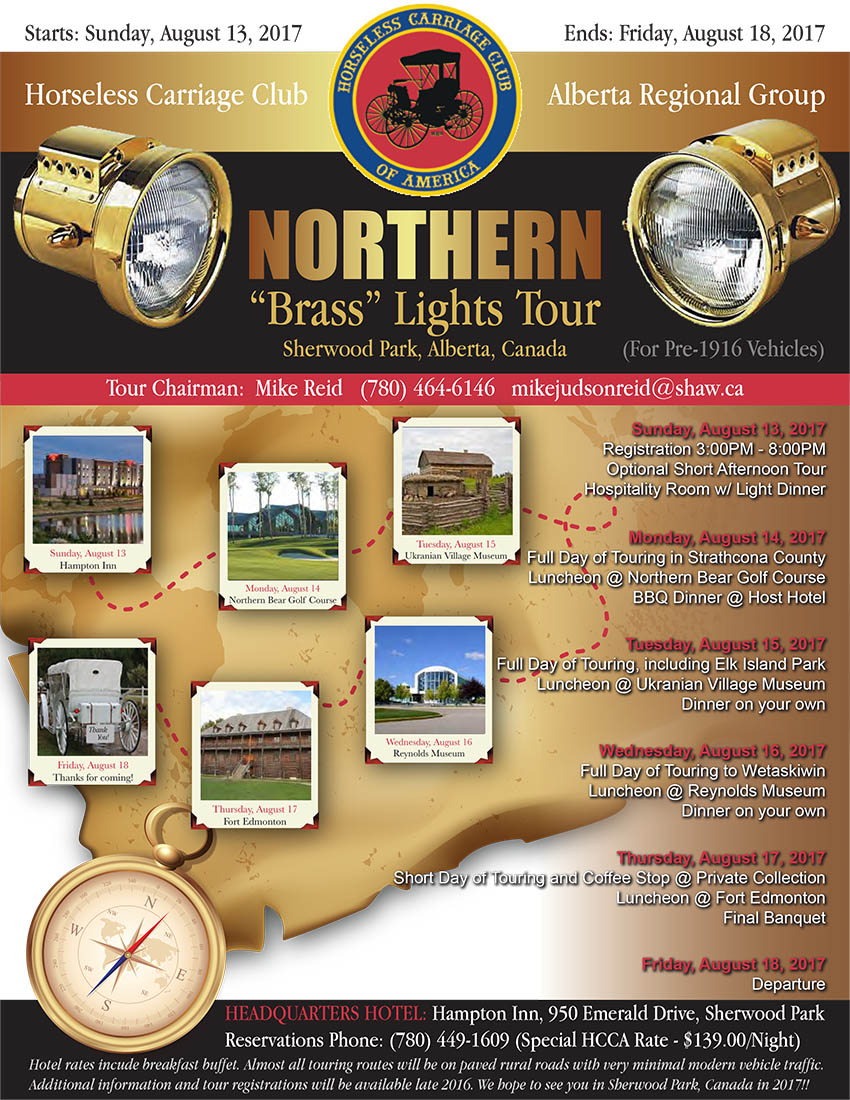

Brass Car Tour

Club Member Mike Reid from Sherwood Park is chairman of the Northern "Brass" Lights Tour based in Sherwood Park. Aug 13-18, 2017

KMS Tools for the World

I learned of this at last Saturday's SVAA meeting. I think it's a great idea. Let's incorporate it into our May parking lot swap meet!

KMS’ Tools for the World is an ongoing program that helps gets tools into the hands of people who need them most around the world.

If you have old tools that are just too good to throw out, and they are taking up space, let your old tools give new hope. Just bring them to any KMS Tools location during store hours, and KMS will get them into the hands of people who could really use them. Volunteers check the tools over, and where possible will repair the tools! KMS’ Tools for the World program has sent numerous pallets of tools to countries such as Haiti, Thailand, Ghana, Malawi, and more. This enables the locals to build and repair homes, schools, churches, and hospitals, and also provides opportunities to set up businesses, employing others in their communities.

Thank you to everyone who has donated and contributed to this program.

KMS’ Tools for the World- your old tools giving new hope.

Drive Safe & Often !

Ross Benedict, President

Foothills Model T Ford Club

403-651-1612

Horse Roundup

As you may know Rod Wallace is a former park warden. He recently sent this link that you may find interesting.

Rear Axle Repair

A couple of years ago at the annual safety check Art Bent discovered stripped threads on one his touring car rear axles. The axle was repaired by cutting new threads with a slightly smaller metric die. This year he decided it was time to replace the axles and rebuild the rear end. As is often the case the initial problem was only the tip of the iceberg.

First the gears were pressed off the old axles. To do this the gear is pressed further onto the axle in order to remove the gear retaining clips. In this photo the end of the axle is resting on a bar at the bottom of the press. The socket allows clearance for the portion of the axle that protrudes through the gear.

Seating the gear on the new axle

The rear end in Art’s car had been previously rebuilt by a mechanic who replaced the old babbit thrust washers with new bronze ones. He did not however replace the worn-out thrust washer retaining pins. One of the thrust washers needed to be replaced so it was used to extract what was remaining of the old pins. The simplest way to extract the pins is to weld them to a worn-out washer or other piece of metal.

Here a piece of flat iron with a hole in it is welded to the sheared off pin.

When the rear end was assembled with the new axles there was too much lash between the ring and pinion and the pinion was in tough shape. Les Schubert offered to come over and help with the project. The castle nut holding the pinion gear was only finger tight and the pinion gear was loose on the taper. Further inspection revealed damage to the Hyatt bearing race.

To be continued